← Back to New

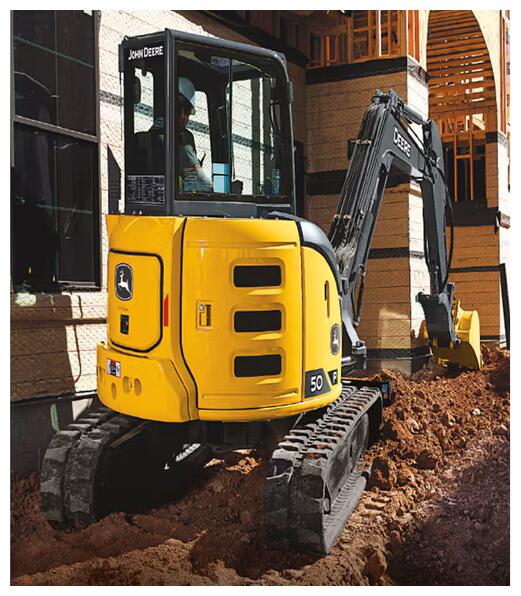

2026 John Deere 50P

Excavator

The John Deere 50P Compact Excavator represents the second-largest compact excavator in John Deere's lineup, featuring zero-tail-swing design that maximizes maneuverability and performance in tight urban and residential jobsites while maintaining impressive lift capacity and reach capabilities. Powered by a Yanmar 4TNV88C 4-cylinder diesel engine with 2.19-liter displacement producing 26.8 kilowatts net power (35.9 horsepower) at 2,400 rpm and meeting EPA Final Tier 4/EU Stage IV emissions standards, this machine delivers efficient power density with advanced fuel-saving features including auto-idle that automatically reduces engine speed when hydraulics aren't in use, auto shutdown that conserves fuel, and selectable power/economy modes that optimize performance for specific digging applications. The 50P features a 2.85-meter boom with choice of 1380mm standard arm achieving 5.75 meters maximum cutting height, 4.07 meters maximum dumping height, 3.53 meters maximum digging depth, and 5.96 meters maximum digging reach, or optional 1690mm long arm configuration (with additional 200kg counterweight) achieving 6.00 meters cutting height, 4.31 meters dumping height, 3.83 meters digging depth, and 6.26 meters reach. With impressive digging forces of 36.8 kilonewtons bucket breakout (8,267 pounds) and 24.0 kilonewtons arm digging force (5,401 pounds) using standard arm, this excavator handles demanding excavation, trenching, and material handling tasks. The machine features independent swing boom providing 80 degrees left and 60 degrees right offset capability combined with 360-degree rotation and 9.0 rpm swing speed using axial-piston swing motor with spring-applied hydraulically-released automatic wet-disc swing brake. Standard 2.00-meter-wide backfill blade (6 feet 7 inches) with 460mm maximum lift above ground and 360mm maximum drop below ground enables grading, filling, and enhanced stability, with optional hydraulic angle blade available. The closed-center load-sensing hydraulic system features one variable-displacement pump delivering 120.0 liters per minute maximum rated flow (31.7 gpm) with auxiliary flow of 87.4 liters per minute (23.1 gpm) supplied to standard quick-coupler-equipped boom-mounted auxiliary hydraulic lines. Hydraulic pilot-operated controls with excavator-to-backhoe pattern change valve provide precise operation of boom, arm, bucket, swing, boom swing, blade, travel, and auxiliary functions, with auxiliary return-flow selector valve accommodating one-way or two-way hydraulic attachments. Auto-idle, auto shutdown, and power/economy modes optimize fuel efficiency and performance. The spacious operator station features wide entryway, choice of standard vinyl seat with fore/aft adjustment or optional cloth suspension seat, foldable travel pedals positioned for efficient operation and comfortable foot room, boom-swing foot control, 51mm retractable seat belt standard with optional 76mm belt available, comprehensive instrumentation including hour meter, fuel gauge with low-fuel indicator, engine oil pressure indicator with alarm, alternator voltage indicator, engine coolant temperature gauge and indicator with alarm, preheat indicator, work lights indicator, and illuminated mode selectors. Standard ROPS/TOPS/FOPS canopy with optional ROPS/TOPS/FOPS cab including air conditioning and heating available, with optional front screen and rear secondary exit kit. Rubber cab mounts and noise-reducing aftertreatment device with isochronous high-idle speed minimize vibration and sound levels. Two-speed hydrostatic axial-piston propel motors with automatic shifting and planetary final drives provide 2.5 km/h low speed (1.6 mph) and 4.2 km/h high speed (2.6 mph), with track speeds automatically slowing when heavier loads encountered then returning to high when load normalizes without operator activation required. Standard 400mm rubber tracks deliver ground pressure as low as 26.9 kPa (3.90 psi) with canopy and standard counterweight configuration, with optional 400mm steel tracks with triple semi-grousers or 400mm rubber crawler pads available. Standard mechanical quick-coupler accepts wide range of John Deere attachments including buckets with various teeth configurations for ditching and heavy-duty applications, hydraulic hammers with points and tools for concrete and rock breaking, planetary and chain-drive augers with multiple bit sizes and adapters, clamps, and compactors. Optional hydraulic wedge-lock and pin-grabber style couplers available for enhanced attachment versatility. Heavy-duty side shields protect boom/blade cylinders and drive motors from material and impacts, while single-pin swing-post increases boom rigidity and reinforced D-channel side frames plus heavy-duty X-frame undercarriage designed to shed dirt and debris extend component wear life. Articulation hose shield protects hydraulic lines. Hinged service-access doors with vandal protection provide wide-open access to side-by-side oil cooler and radiator with cooler design that resists trash buildup, while operator station tilts forward 50 degrees for major service access to swing motor, hydraulic control valve, engine starter motor, and alternator. Extended maintenance intervals including extended oil change and greasing intervals with oil-impregnated bushings contribute to low daily operating costs and increased uptime. Track adjusters located in each track frame can be adjusted using standard high-pressure grease gun, with track sag adjustment conveniently located in center of frame to maintain proper tension and maximize undercarriage life. Sprocket center to idler center measures 2.00 meters with 2.50-meter track length. Standard 700kg counterweight (1,543 pounds) with optional additional 200kg counterweight (441 pounds) required for long arm configuration. Lift capacities at 3.05-meter radius over front with blade down and standard arm: 2,511kg with canopy and standard counterweight, 2,511kg with cab and standard counterweight, 2,511kg with canopy and extra counterweight, 2,511kg with cab and extra counterweight (hydraulically limited). Fluid capacities include 70-liter fuel tank (18.5 gallons), 56-liter hydraulic tank (14.8 gallons), 8.6-liter engine oil with filter (9.1 quarts), and 5.0-liter cooling system (5.3 quarts). Standard equipment includes 55-amp alternator, two halogen work lights (one mounted on operator station and one on boom), 12-volt accessory outlet, low-maintenance battery with positive-terminal covers, blade-type multi-fused circuits, engine preheater, fuel/water separator, full-flow oil filter, isolation-mounted engine, key start switch with electric fuel shutoff, single dry-type air filter, fan guard, motion alarm with cancel switch, horn, toolbox, tie-down provisions, and propel motor shield. Optional JDLink connectivity hardware enables John Deere Operations Center account access for machine data analysis, utilization tracking, diagnostic alerts monitoring, and Connected Support for proactive issue resolution with remote dealer monitoring capabilities. Operating weight with canopy, standard arm, rubber tracks, straight blade, full fuel tank, standard counterweight, and 79kg operator is 4,790 kilograms (10,560 pounds), or 4,920 kilograms (10,847 pounds) with cab. Machine dimensions include 1.85-meter upperstructure width (6 feet 1 inch), 2.53-meter overall height with canopy or cab (8 feet 4 inches), 2.00-meter undercarriage width (6 feet 7 inches), 340mm ground clearance (13 inches), 1.00-meter tail swing radius with standard arm (39 inches) or 1.10 meters with long arm and extra counterweight (43 inches), 1.59-meter engine cover height (5 feet 3 inches), 610mm counterweight clearance (24 inches), and 5.47-meter transport length with standard arm (17 feet 11 inches) or 5.52 meters with long arm (18 feet 1 inch). The compact stature permits easy transport between jobsites perfect for dig-and-go projects while zero-tail-swing configuration enables operation in confined spaces with minimal risk of damaging surrounding structures.

Interested in this excavator?

Contact us for pricing, availability, and more information.

Phone: (845) 482-5222

Email: mullallytractor@gmail.com

Address: 4510 State Route 52, Jeffersonville, NY 12748

Store Hours: Mon-Fri 8am-5pm, Sat 8am-12pm, Sun closed